Investigation Underway to Determine Cause of Boeing Airliner Fuselage Incident

Investigators are currently searching for the piece of fuselage that blew off a Boeing airliner over Oregon on Friday. The objective is to gather physical evidence in order to determine what went wrong.

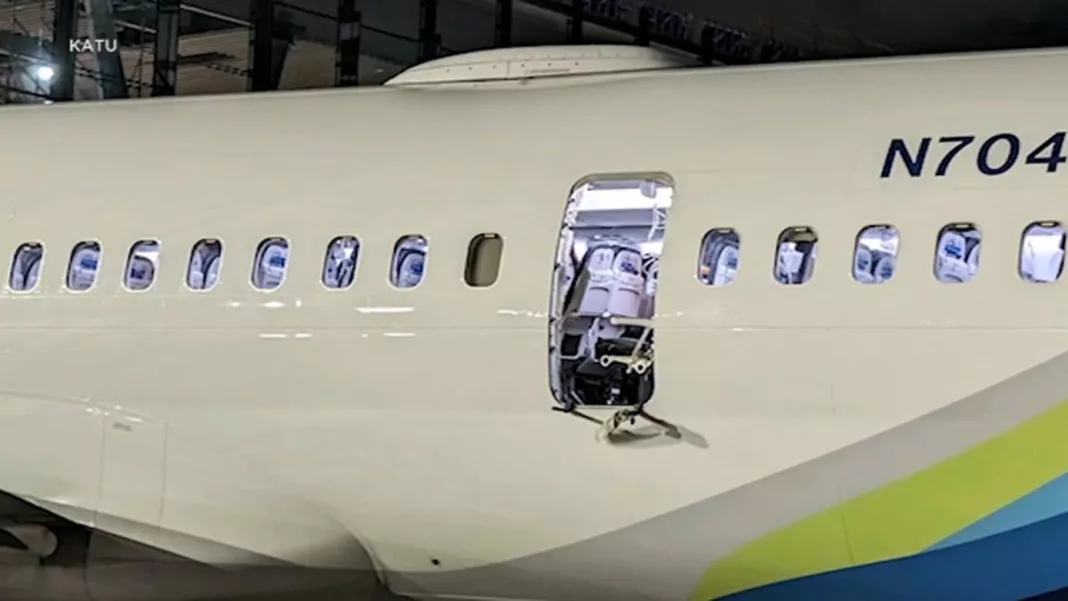

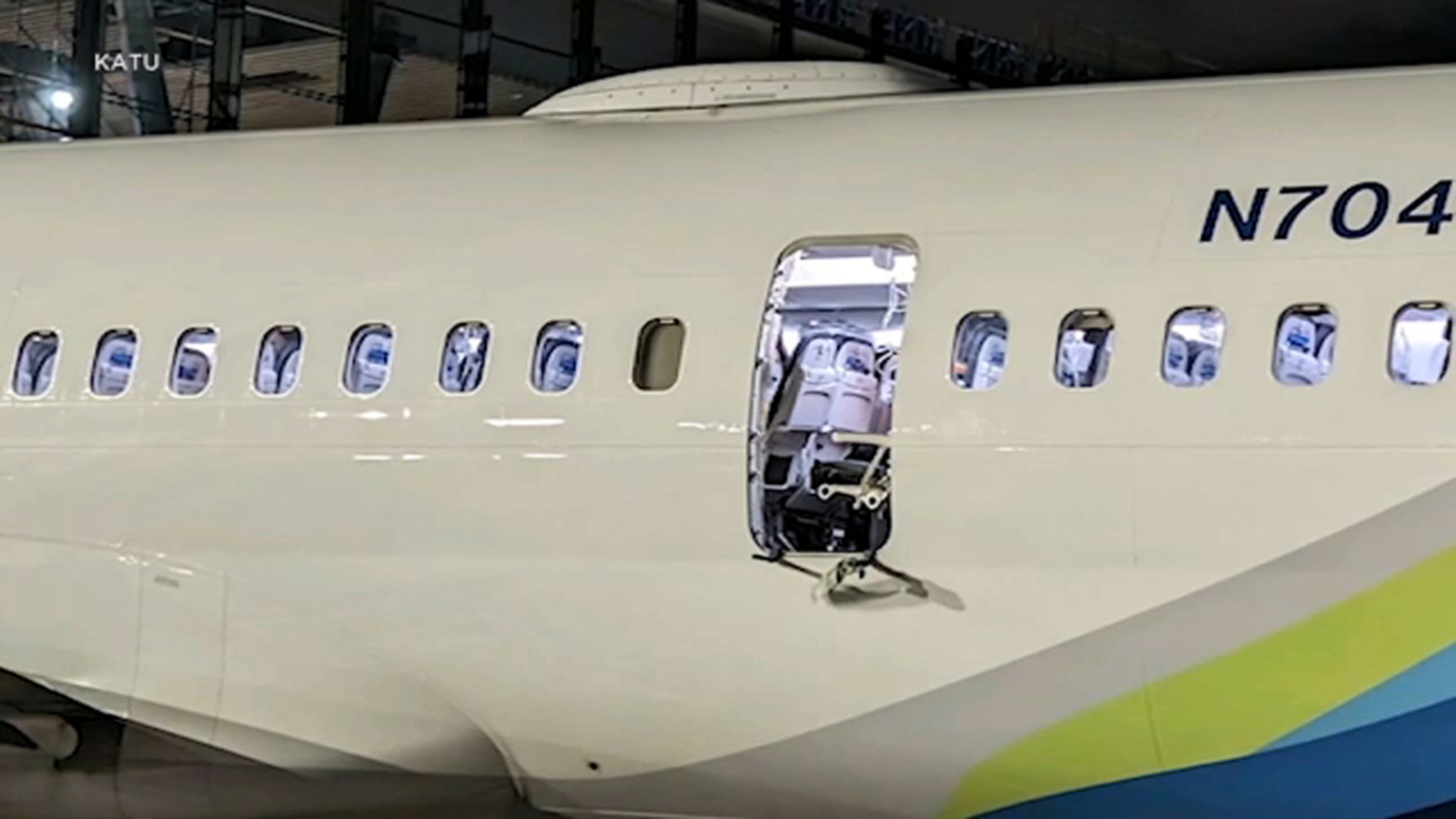

The incident occurred on an Alaska Airlines jet, where a large hole appeared on the side of the aircraft. This hole is located where Boeing typically installs a “plug” to cover an emergency exit that the airline does not use.

Most Boeing 737 Max 9 jets have these plugs, and as a result, the Federal Aviation Administration (FAA) has temporarily grounded these planes until inspections of the area surrounding the door plug are completed.

Why is the plug there?

According to federal regulations, larger Boeing 737s must have emergency exits on the fuselage behind the wings to ensure passengers can evacuate within 90 seconds, even if half of the exits are blocked. The number of passenger seats on a plane determines the required number of exits.

Some airlines, such as Lion Air and Corendon Dutch Airlines, have more than 200 seats on their Max 9s, necessitating extra emergency exits. However, Alaska Airlines and United Airlines configure their 737 Max 9s with fewer than 180 seats, allowing them to comply with U.S. evacuation rules without the two mid-cabin exits.

On Alaska and United planes, the side exits near the back are replaced with a permanent plug that matches the size of an exit door.

Are these plugs exclusive to Max 9s?

No, Boeing also produces larger versions of its 737-900 and the Max 8, which have space for additional exits in the back. Buyers of these planes can choose to install either exit doors or plugs.

Who installs the plugs?

Spirit AeroSystems, a major supplier for Boeing, confirmed that they installed door plugs on Max 9s, including the one involved in the recent incident with Alaska Airlines. The assembly of door plugs takes place at Spirit’s factory in Wichita, Kansas.

Both Spirit AeroSystems and Boeing declined to comment on the issue.

The Boeing supplier

Spirit AeroSystems is Boeing’s primary supplier for commercial planes, manufacturing fuselages and other components for Boeing Max jets. The company has faced quality control issues in the past, including improperly drilled fastener holes in 737 Max jets discovered last year.

The investigation

The National Transportation Safety Board (NTSB) has initiated an investigation into the incident. The NTSB team, led by chair Jennifer Homendy, arrived in Portland, Oregon, to begin their examination. The investigation is expected to last at least a year.

The team includes a metallurgist who will examine the exit-door plug, hinges, and other relevant parts if they are found. Experts believe that analyzing the damage to the door will be crucial in determining the cause of the failure.

Anthony Brickhouse, an accident investigation instructor at Embry-Riddle Aeronautical University, expressed confidence that the missing piece will be located and provide scientific insight into the incident. He noted that exit doors, whether plugged or not, are not typically considered weak points in the fuselage.

Were there any warnings?

Aerospace analysts from Jefferies, an investment bank, reported that the plane involved in the incident experienced pressurization issues on two previous flights. The NTSB has not commented on the plane’s history but stated that maintenance records will be examined.

Other fuselage blowouts

While rare, there have been instances of holes opening in the fuselages of airliners. These incidents are often attributed to metal fatigue in the plane’s aluminum skin.

In 1988, a flight attendant for Aloha Airlines was tragically blown out of the cabin of a Boeing 737 over the Pacific Ocean when a large section of the roof peeled away. This incident led to stricter regulations regarding the inspection and repair of microscopic fuselage cracks.

In 2009, a hole opened in the roof of a Southwest Boeing 737 flying over West Virginia, and in 2011, a 5-foot-long gash appeared in another Southwest Boeing 737, resulting in an emergency landing in Arizona. Both cases were attributed to metal fatigue and caused no injuries.